The technology

The optical heterodyne sampling technology (known as ASOPS) developed by Neta has been designed to characterize thin films. This patented technique is suitable for a wide range of Applications. Indeed, it performs without contact and without damage, this way, it does not represent any risk for the tested material.

Non-destructive, contactless measurement

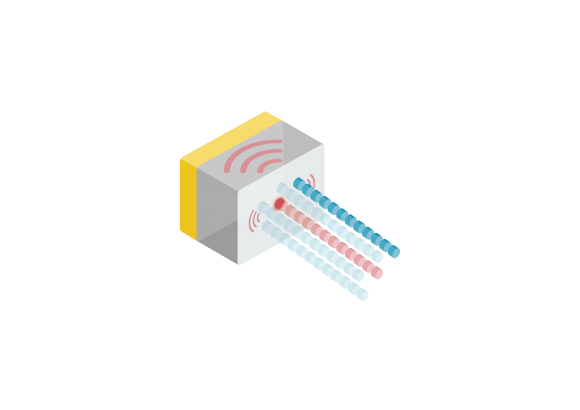

NETA technology uses two synchronized ultrafast lasers and an acquisition chain designed in our R&D office.

Whichever the technique is used, it generates laser pulses of around 100 femtoseconds with different wavelengths. Non-destructive and non-contact measurement is carried out using these pulses. These are focused on the surface of the sample under study.

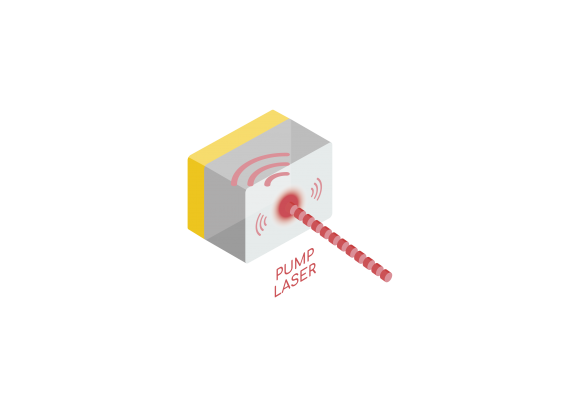

The absorption of the first ''pump'' pulse by the sample induces a very short transitory change in its optical properties.

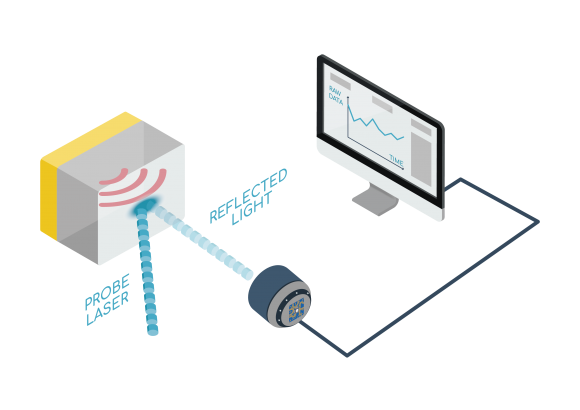

The second ''probe'' pulse enables the physical state of the sample to be recorded, thanks to the reflection or transmission index of the sample.

A wide range of measurable parameters

NETA technology allows for the characterization of thin films and gives access to the thickness of a single layer and multilayers. The mechanical and thermal properties of the materials measured also make it possible to evaluate the adhesion of a material.

Surface Acoustic Wave (SAW) mode provides access to additional mechanical surface parameters

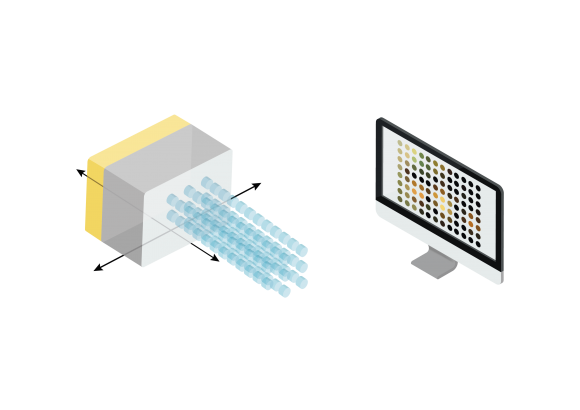

Image mode provides a high definition map of the nanometric structures studied

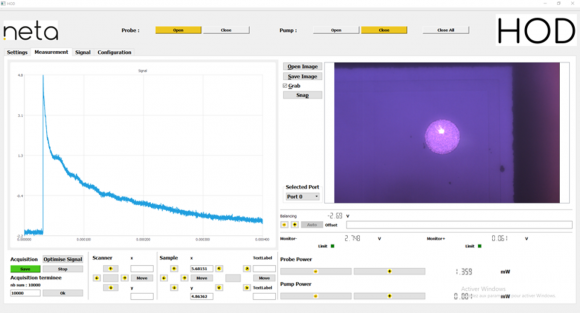

Software made by NETA

NETA places its users at the heart of its concerns and has developed software that integrates an interface allowing optimum use of the system's capacities and parameters.

Our software offers unique performance and unprecedented ease of use.

Main features of our technology

- Non-destructive and contactless technique

- Characterization of thin films: thickness, adhesion, thermal property

- Fast and repeatable measurement

- Ultra-precise measurement

- 3D sample

- Many materials available